Optimal speed range is 10007000 ftmin 3002130 mmin. Input power can be split among several driven pulleys by using a power ratio factor for each pulley.

V Belts Design Requirements For Power Requirements Angle Between Sheave

Drive torque P2πn 1 Nm.

. Companion pulleys contain integral spokes which run radially on the pulley. Divide the design power with the corrected power rate of the v-belt. To meet all the expectations of the market Hutchinson has expanded its product portfolio with a range of Hutchinson V-belts timing belts and pulleys.

Lets say that you own a factory and you need to calculate a v-belt length. This produces a high strength-to-weight ratio advantageous to fractional horsepower pulleys. IS0 4183-1989 Belt drives - Classical and narrow V-belts - Grooved pulleys system based on datum width.

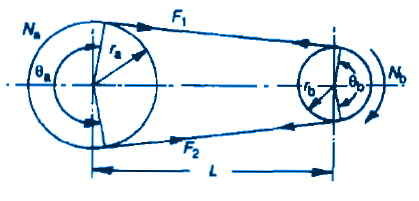

V-belts trump flat belts with their small center distances and high reduction ratios. Effective friction coefficient μ μsinβ2- Ratio of belt forces T 1 T 2 expμα- Belt tension load T 1 T 1-T 21-T 2 T 1 N. V-Belt Pulley Design Calculation.

The RPM of the first driven large pulley is transferred to second set small driver pulley and. V belt speed fpm 12 Driver RPM Driver Pitch Diameter in π. The formula for mechanical advantage is.

Smartphone version on Apple Store and Google Play Store. Hutchinson develops and manufactures complete power transmission system incorporating ribbed belts for HVAC Conveying industrial motors agriculture and energy supply markets. Horsepower HP Tq.

Typical calculation design of a transmission using a V-belt consists of the following steps. V-belts need larger pulleys for their thicker cross-section than flat belts. To calculate the total load inertia of the motor shaft conversion value.

See Table 2 below for typical values. Pd design power as determined in Section 311 W belt weight per foot of length lb. D is Diameter in millimeters F is Face Width in millimeters.

These calculations are mainly for existing installations but you could also put it towards your design if you want to calculate what the length needs to be of the belt as long as you already know the distance between the two pulleys and the size of the pulleys. Dynamic balancing is strongly recommended in applications running at high speeds. Industrial V-belts classical V-belts have been covered in IS 2494 Part 1.

Tension calculator for V-belt. RPM of small sheave Power HP Pe x V 33000 HP. D L 30 cm 03 m.

FIRST APPROACH FOR ELECTRIC ENGINE. Belt speed feet per minute d. This approach is only valid for electric engines and Poly V belts.

To calculate belt length enter size of. The value of transmission power used in designing is the power requirement of the driven machine if obtained or the power of driving unit engine or motor. International Organization for Standardization IS0.

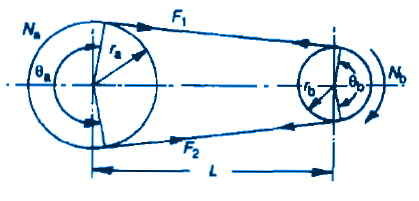

For the total design of power transmission belt we recommend our Application designing program for belts it can be downloaded at. RPM of small sheave Power HP Tq x n 63025 HP. Note that the units are not relevant as long as theyre the same for all variables.

For example if you found 271 you must use 3. The number of belts required for an application is obtained by dividing the design horsepower by the corrected horsepower rating for one belt. Effective pull pounds V.

A mechanical advantage greater than 1 means that we can accomplish the work with lesser force but exerting it for a greater distance. Shaft load F a. Design process for Classical V-Belts Narrow V-Belts.

Belt Speed V d x n 382 V. 14 Set the mode of loading and operational parameters type of. Torque pounds-inches n.

The corrected horsepower rating of one belt is obtained by multiplying the horsepower rating from. 1993 V-belts - Endless. Multiply the correction factors that you found in step 11 with the power rate to find the corrected power rate of the selected standard v-belt.

D is Diameter in inches F is Face Width in inches. To determine whether dynamic balancing is advisable perform the following calculation. D S 15 cm 015 m.

Belt drive power transmission. Standard pulleys are pulleys that have traditional dimensions with one or multiple grooves which mate with classic small-engine and hexagonal-style v-belts. Other belts Flexonic Conveyxonic.

By an Hutchinson skilled engineer experienced in drive belt systems. Horsepower HP Pe. Belt tension load T 2 T 1 T 2 T 1.

Small sheave pitch diameter inches n. RPM 2554 x 15500 DF 12. The forces and torques are calculated accordingly.

Convert the value from torque Tq or horse power PS into kW with the formula below. The preferred center distance is larger than the largest pulley diameter but less than three times the sum of both pulleys. Input the values into the equation.

Smallest belt wrap angle α. Enter power parameters of the transmission transferred power speed. L 15 m.

Belt speed feet per minute Torque Tq Pe x d 2. If youre unsure most are rated at 3600. RPM 15500 DF 12.

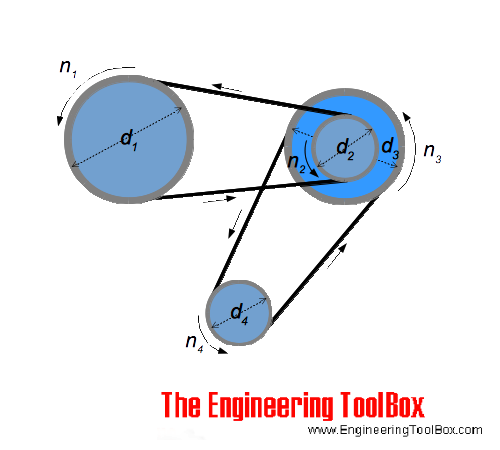

The diameters of the pulleys are 15 and 30 cm and you want the distance between them to be 15 meters. Belt speed v π D 1 n 1. Multiple Pulley Sets - RPM Reduction.

Our Application Technology experts offer you free support service regarding the application of our products and also help. Mechanical Advantage Output ForceInput Force A mechanical advantage of 1 means that the input force is equal to the output force. Drive force T 1-T 2 Pv.

To calculate multiple pulley sets where the first driven large pulley shaft drives the second driver small pulley and so on enter Initial Small Pulley RPM Number of Sets and Small Diameter Large Diameter and Centers of each Set below. V-BELT DRIVES This technical manual contains all important technical information and methods for the design and calculation of drives with Optibelt V-belts and V-grooved pulleys for industrial applications. Vee Belts V Belts Roy Mech L belt pitch length.

V W N V P 1 60 09 10 3 2 where. Accurately design comprehensive V-Belt transmissions with two or three pulleys by relying on this user-friendly and advanced Excel calculator. Arc of contact correction factor c 1 The arc of contact correction factor corrects the power rating of the V-belt for pulleys where the arc of the contact differs from 180 degrees.

Two Pulley Connecting Belt Design And Calculations

V Belt Calculation And Design Mitcalc 02 Youtube

V Belts Design Procedure Youtube

Belts Pulley Diameters Vs Speed

Pulley Belt Calculations The Engineering Mindset

Danotes V Belt Drives Introduction

V Belts Design Requirements For Power Requirements Angle Between Sheave

0 comments

Post a Comment